- Sizing the System Incorrectly

- 2. Not Considering Ductwork

- Ignoring Insulation

- Neglecting Airflow

- 5. Overlooking Electrical Requirements

- Forgetting About Maintenance

- Installing the Unit in the Wrong Location

- Not Leveling the Unit Properly

- Failing to Secure the Unit

- Not Connecting the Refrigerant Lines Properly

- 11. Not Charging the System with Refrigerant Properly

- Not Testing the System Properly

- Not Getting a Permit

- Popular Questions: What Are The Common Mistakes To Avoid When Installing An HVAC System?

What are the common mistakes to avoid when installing an HVAC system? – When embarking on the installation of an HVAC system, it is imperative to navigate the potential pitfalls that may arise. This academic presentation delves into the common mistakes to avoid, guiding you through the intricacies of sizing, ductwork, insulation, airflow, electrical requirements, maintenance, location, leveling, securing, refrigerant lines, charging, testing, and permitting.

By avoiding these missteps, you can ensure a seamless installation, optimal system performance, and long-term reliability.

Sizing the System Incorrectly

Properly sizing an HVAC system is crucial to ensure efficient and effective climate control within a space. An appropriately sized system can maintain desired temperatures, minimize energy consumption, and extend the system’s lifespan. Conversely, systems that are too large or too small can lead to a range of issues and inefficiencies.

Determining System Size

Calculating the appropriate size for an HVAC system involves considering several factors, including the square footage of the space, insulation levels, number of occupants, and climate conditions. A common method for determining system size is through Manual J, a standardized calculation developed by the Air Conditioning Contractors of America (ACCA).

When installing an HVAC system, it is crucial to avoid common mistakes such as improper sizing, poor ductwork design, and incorrect refrigerant charge. These errors can lead to inefficient operation, reduced comfort levels, and increased energy consumption. Additionally, it is important to follow the manufacturer’s instructions carefully to ensure proper installation and operation.

For example, when setting up a Samsung printer, you can refer to the samsung easy printer manager einrichten guide for detailed instructions. By avoiding these common mistakes and following the manufacturer’s guidelines, you can ensure that your HVAC system operates efficiently and effectively, providing optimal comfort and energy savings.

This method considers all relevant factors to determine the heating and cooling loads of a space, which in turn guides the selection of an appropriately sized system.

Ductwork Considerations

Ductwork plays a vital role in system sizing and performance. Undersized ductwork can restrict airflow, leading to reduced efficiency and increased noise levels. Oversized ductwork, on the other hand, can result in excessive static pressure, which can strain the system and shorten its lifespan.

Proper ductwork sizing ensures optimal airflow, minimizing pressure drops and maximizing system efficiency.

Common System Sizes and Applications

The table below provides a general overview of common HVAC system sizes and their recommended applications:| System Size (BTU/hr) | Recommended Application ||—|—|| 18,000-24,000 | Small homes (up to 1,500 sq. ft.) || 24,000-30,000 | Medium-sized homes (1,500-2,500 sq. ft.) || 30,000-36,000 | Large homes (2,500-3,500 sq.

ft.) || 36,000-48,000 | Very large homes (over 3,500 sq. ft.) || 48,000+ | Commercial buildings |

2. Not Considering Ductwork

Ductwork is an essential component of an HVAC system, responsible for distributing conditioned air throughout the building. Ignoring ductwork during installation can lead to inefficient system operation and poor indoor air quality.Ductwork comes in various types, each with advantages and disadvantages:

Sheet metal ducts

Durable, affordable, and customizable.

Flexible ducts

Easy to install, but less durable and efficient.

Fiberboard ducts

Lightweight and insulated, but prone to moisture damage.Proper ductwork design and installation involve:

- Sizing ducts correctly to ensure adequate airflow.

- Minimizing bends and elbows to reduce pressure loss.

- Insulating ducts to prevent condensation and heat loss.

- Sealing joints and connections to prevent air leakage.

Ignoring Insulation

Properly insulating the ductwork and other components of an HVAC system is crucial for its efficient operation. Insulation prevents heat loss in heated spaces and heat gain in cooled spaces, reducing energy consumption and lowering utility bills.

Types of Insulation

Various types of insulation are available for HVAC systems, including fiberglass, cellulose, and spray foam. Fiberglass is a cost-effective option with good thermal resistance. Cellulose is made from recycled paper and offers high insulation value. Spray foam is a more expensive option but provides excellent air sealing and insulation.

Installing Insulation Correctly

Proper insulation installation is essential for optimal performance. Ductwork should be sealed with mastic or tape to prevent air leaks. Insulation should be installed tightly around the ductwork, with no gaps or voids. Adequate insulation thickness should be maintained to meet the recommended R-value for the climate zone.

Consequences of Improper Insulation

Neglecting insulation can significantly affect HVAC system efficiency. Uninsulated ductwork leads to heat loss or gain, reducing the system’s ability to maintain desired temperatures. This results in increased energy consumption and higher utility bills.

Benefits of Insulation, What are the common mistakes to avoid when installing an HVAC system?

Proper insulation can reduce energy consumption by up to 20%. It helps maintain comfortable indoor temperatures, reducing the need for excessive heating or cooling. Insulation also improves air quality by preventing condensation and mold growth within the ductwork.

Neglecting Airflow

Neglecting airflow in an HVAC system can lead to a multitude of problems, including reduced energy efficiency, poor indoor air quality, and increased risk of system failure. Therefore, it is crucial to ensure that proper airflow is maintained throughout the system.Airflow is essential for the efficient operation of an HVAC system.

It helps to distribute conditioned air throughout the space being conditioned, ensuring that all areas are adequately heated or cooled. Proper airflow also helps to remove stale air and contaminants from the indoor environment, improving indoor air quality. Additionally, adequate airflow helps to prevent the system from overheating or freezing up, reducing the risk of system failure.

Factors Affecting Airflow

Several factors can affect airflow in an HVAC system, including:

- Ductwork design and installation:Improperly designed or installed ductwork can restrict airflow, reducing the efficiency of the system.

- Filter maintenance:Dirty or clogged filters can block airflow, reducing the system’s performance.

- Equipment sizing:Oversized or undersized equipment can lead to airflow problems.

Tips for Promoting Good Airflow

To design and install an HVAC system that promotes good airflow, it is important to:

- Use proper duct sizing and layout:Ductwork should be sized and installed according to industry standards to ensure adequate airflow.

- Ensure adequate filter capacity:Filters should be sized and replaced regularly to maintain proper airflow.

- Match equipment capacity to the size of the space being conditioned:Oversized or undersized equipment can lead to airflow problems.

5. Overlooking Electrical Requirements

Proper electrical requirements are crucial for the safe and efficient operation of an HVAC system. Ignoring these requirements can lead to safety hazards, system malfunctions, and reduced efficiency.

An HVAC system requires a dedicated electrical circuit with the appropriate voltage, amperage, and wiring to handle the power demands of the system. The electrical connection must be made by a qualified electrician to ensure compliance with electrical codes and safety standards.

Types of Electrical Connections

- Single-phase connection:Used for small residential systems, this type of connection requires a single circuit with two wires (hot and neutral) and a ground wire.

- Three-phase connection:Used for larger commercial and industrial systems, this type of connection requires three circuits with three hot wires, a neutral wire, and a ground wire.

Troubleshooting Electrical Problems

- Check the circuit breaker or fuse:If the HVAC system is not receiving power, the circuit breaker or fuse may have tripped or blown. Reset the breaker or replace the fuse if necessary.

- Inspect the wiring:Loose or damaged wiring can cause electrical problems. Inspect the wiring for any signs of damage or wear and replace as needed.

- Contact a qualified electrician:If you are unable to resolve the electrical problem yourself, contact a qualified electrician for assistance.

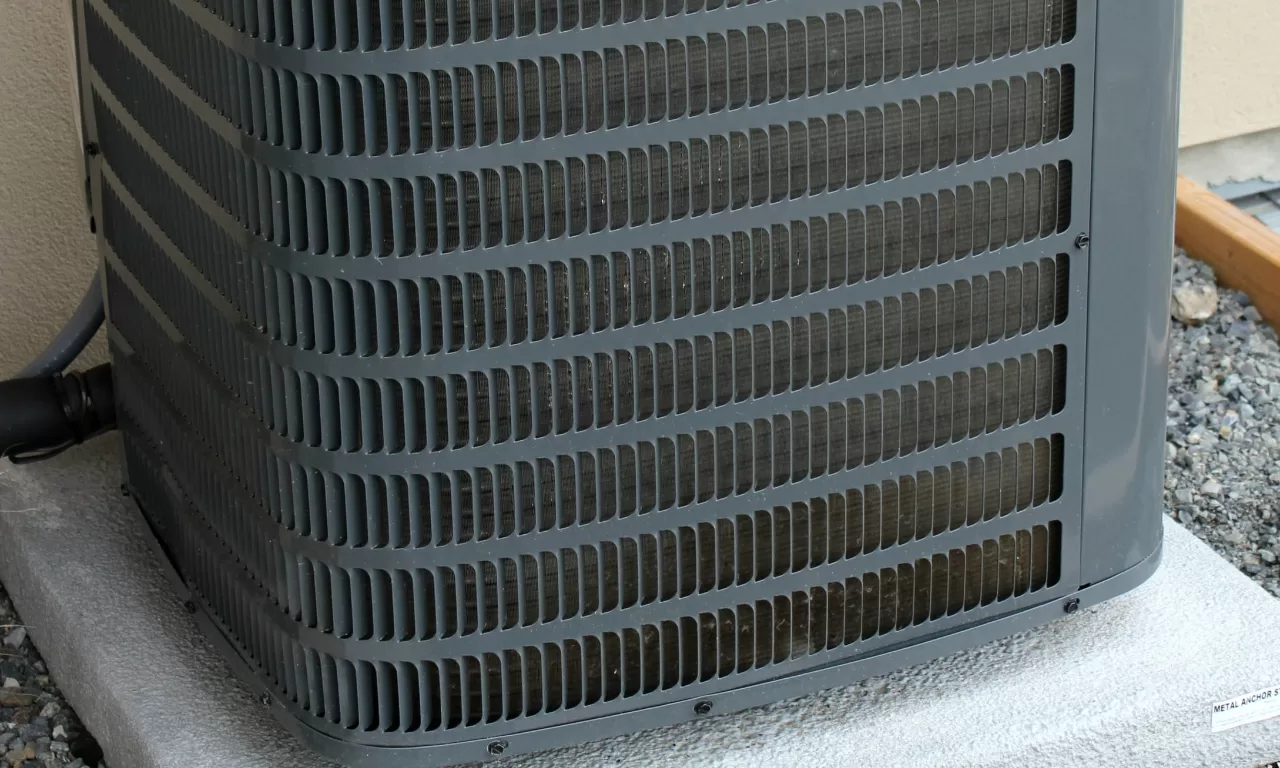

Forgetting About Maintenance

Regular maintenance is crucial for the longevity, efficiency, and safety of an HVAC system. Overlooking maintenance can lead to costly repairs, premature system failure, and increased energy consumption.HVAC maintenance involves various tasks that should be performed regularly to ensure optimal system performance.

These tasks include:

Filter Replacement

Regularly replacing air filters (every 1-3 months) helps remove airborne particles, preventing them from clogging the system and reducing airflow.

Coil Cleaning

Cleaning the evaporator and condenser coils (annually or semi-annually) removes dirt, debris, and mold that can obstruct heat transfer and reduce efficiency.

Refrigerant Level Check

Checking refrigerant levels (annually) ensures proper system operation and prevents overheating or compressor damage.

Electrical Inspection

Inspecting electrical components (annually) helps identify any loose connections, faulty wiring, or potential safety hazards.

Lubrication

Lubricating moving parts (as per manufacturer’s recommendations) reduces friction, wear, and tear, extending system lifespan.

Installing the Unit in the Wrong Location

Choosing the right location for an HVAC unit is essential for ensuring its optimal performance and efficiency. Installing the unit in the wrong place can lead to several problems, including reduced cooling or heating capacity, increased energy consumption, and premature failure.

When selecting a location for an HVAC unit, several factors should be considered:

- Accessibility:The unit should be easily accessible for maintenance and repairs.

- Airflow:The unit should be placed in a location with good airflow to prevent overheating and ensure efficient operation.

- Sunlight:The unit should be protected from direct sunlight, as exposure to UV rays can damage the components.

- Proximity to other appliances:The unit should not be placed near other appliances that generate heat, such as furnaces or water heaters, as this can interfere with its operation.

- Noise:The unit should be placed in a location where the noise it produces will not be disruptive to occupants.

To find the best location for an HVAC unit, it is recommended to consult with a qualified HVAC technician. They can assess the specific requirements of the building and recommend the optimal location for the unit.

Not Leveling the Unit Properly

Installing an HVAC unit requires precision and attention to detail, and leveling the unit properly is a crucial aspect often overlooked. Failure to level the unit can lead to a range of issues, affecting its performance, efficiency, and lifespan.

An unleveled HVAC unit can cause uneven cooling or heating, as the refrigerant may not distribute evenly throughout the system. This can result in some rooms being too cold or too warm, compromising comfort levels and increasing energy consumption.

Importance of Using a Level

Using a level is essential to ensure the HVAC unit is installed evenly on all sides. This prevents the unit from leaning or tilting, which can cause strain on the components and lead to premature failure.

How to Use a Level

To use a level, place it on top of the unit and check if the bubble is centered. If the bubble is not centered, adjust the unit’s legs or base until it is level.

Tips for Leveling the Unit

- Use a level that is at least 2 feet long for accuracy.

- Check the level in multiple directions to ensure the unit is level from all sides.

- If the unit is not level, adjust the legs or base by turning them clockwise or counterclockwise until the bubble is centered.

Consequences of Not Leveling the Unit

- Uneven cooling or heating

- Increased energy consumption

- Premature component failure

- Reduced lifespan of the unit

How to Avoid Not Leveling the Unit

To avoid the consequences of not leveling the unit properly, it is crucial to use a level during installation and ensure the unit is level before securing it in place.

Short Story

In a small town, a homeowner decided to install a new HVAC unit in their home. However, they neglected to level the unit properly, resulting in an uneven distribution of refrigerant. This led to uneven cooling throughout the house, with some rooms being too cold and others too warm.

The homeowner soon noticed an increase in their energy bills and frequent breakdowns of the unit due to the strain on the components. Ultimately, the homeowner had to spend more money to have the unit leveled correctly and replaced the damaged components, a costly mistake that could have been avoided with proper installation.

Failing to Secure the Unit

Securing an HVAC unit is crucial for ensuring its proper functioning, longevity, and safety. Failing to secure the unit can lead to various problems and even hazards.

Consequences of Not Securing the Unit Properly

Damage to the Unit

An unsecured unit can be easily knocked over or shifted, damaging its components and compromising its performance.

Noise and Vibration

A loose unit can vibrate excessively, creating noise and discomfort for occupants.

Water Damage

An unsecured unit may not be level, allowing water to accumulate and damage its electrical components.

Safety Hazards

A loose unit can fall or shift, posing a safety hazard to people and property.

Tips for Securing an HVAC Unit Correctly

Use Bolts or Screws

Secure the unit to the ground or a platform using bolts or screws. Ensure the fasteners are appropriate for the unit’s weight and the surface it’s mounted on.

Install Anti-Vibration Pads

Place anti-vibration pads under the unit to reduce noise and vibration.

Use a Weatherproof Sealant

Apply a weatherproof sealant around the base of the unit to prevent water damage.

Install a Security Cage or Enclosure

Protect the unit from theft or vandalism by installing a security cage or enclosure.

Conclusion

Following the manufacturer’s instructions for securing the unit is essential to ensure its safe and efficient operation. By taking the necessary steps to secure the unit, you can prevent potential problems and extend its lifespan.

Not Connecting the Refrigerant Lines Properly

Refrigerant lines are essential components of an HVAC system, carrying refrigerant between the indoor and outdoor units. Proper installation of these lines is crucial to ensure the system’s efficient operation and longevity.

Incorrectly connecting the refrigerant lines can lead to severe consequences, including:

- Refrigerant leaks:Improper connections can create gaps or leaks in the lines, allowing refrigerant to escape. This can compromise the system’s cooling capacity and lead to environmental concerns.

- System failure:Refrigerant leaks can cause the system to malfunction or even fail completely, requiring costly repairs.

- Reduced cooling efficiency:Leaks or improper connections can restrict refrigerant flow, reducing the system’s ability to cool effectively.

- Increased energy consumption:Inefficient cooling due to refrigerant leaks or improper connections can lead to increased energy usage and higher utility bills.

To avoid these issues, it is essential to connect the refrigerant lines correctly. Here are some tips:

- Use the correct tools and materials, including a torque wrench and flare nuts.

- Follow the manufacturer’s instructions carefully, including the recommended torque settings.

- Properly tighten all connections to prevent leaks.

- Vacuum the system to remove air and moisture, which can impair refrigerant flow.

Step-by-Step Guide to Connecting Refrigerant Lines Correctly

- Measure and cut the refrigerant lines to the appropriate length.

- Flare the ends of the lines using a flaring tool.

- Apply a sealant to the flared ends.

- Tighten the flare nuts onto the refrigerant ports, following the manufacturer’s torque specifications.

- Vacuum the system using a vacuum pump to remove air and moisture.

- Charge the system with refrigerant according to the manufacturer’s specifications.

By following these guidelines, you can ensure that the refrigerant lines are connected properly, minimizing the risk of leaks, system failure, and reduced cooling efficiency.

11. Not Charging the System with Refrigerant Properly

The refrigerant charge is a critical factor in the performance of an HVAC system. Too little refrigerant can lead to poor cooling or heating, while too much refrigerant can damage the compressor. It is important to charge the system with the correct amount of refrigerant, and to do so properly.

There are a few reasons why it is important to charge the system with refrigerant properly.

- To ensure the system operates efficiently

- To prevent damage to the compressor

- To prevent leaks

There are a few things that can happen if the system is not charged with refrigerant properly.

- The system may not cool or heat properly.

- The compressor may overheat and fail.

- Refrigerant leaks can occur.

To avoid these problems, it is important to charge the system with refrigerant properly. This should be done by a qualified HVAC technician.

Here are a few tips on how to charge the system with refrigerant properly:

- Use the correct type of refrigerant for the system.

- Follow the manufacturer’s instructions for charging the system.

- Use a refrigerant scale to measure the amount of refrigerant that is added to the system.

- Check for leaks after the system has been charged.

Not Testing the System Properly

Testing an HVAC system after installation is crucial to ensure it operates efficiently and meets the desired performance criteria. Skipping this step can lead to costly problems and discomfort for occupants.

Importance of Testing

Proper testing verifies that the system:

- Cools or heats effectively

- Maintains desired temperatures

- Distributes air evenly throughout the space

- Operates quietly and without excessive vibrations

- Meets safety standards

Tests to Perform

- Temperature Test:Measure temperatures at various points in the space to ensure even distribution and desired comfort levels.

- Airflow Test:Use an anemometer to measure airflow velocity and ensure it meets design specifications.

- Electrical Test:Check voltage, amperage, and continuity of electrical connections to prevent electrical hazards.

- Refrigerant Charge Test:Verify that the system has the correct amount of refrigerant to ensure optimal performance.

- Safety Test:Ensure that all safety devices, such as smoke detectors and carbon monoxide detectors, are functioning properly.

Troubleshooting

If problems are detected during testing, troubleshooting is necessary.

Common mistakes when installing an HVAC system include neglecting proper duct sizing, which can lead to insufficient airflow and reduced system efficiency. Additionally, failing to account for adequate electrical capacity can result in tripped circuit breakers or even electrical fires.

Furthermore, samsung easy printer manager wont open if the refrigerant lines are not properly sealed, leaks can occur, compromising system performance and posing safety hazards. To avoid these issues, it is crucial to consult with qualified HVAC professionals and adhere to industry best practices.

- Check for loose connections:Ensure that all electrical and refrigerant connections are tight and secure.

- Inspect filters:Dirty filters can restrict airflow and reduce system efficiency.

- Clear blockages:Obstructions in ductwork or around the outdoor unit can impede airflow.

- Check thermostat settings:Ensure that the thermostat is set to the desired temperature and operating mode.

- Contact a qualified technician:For complex issues, it is advisable to consult a professional HVAC technician for further diagnosis and repair.

Automated Testing

Automated testing tools can streamline the testing process and provide accurate results. These tools typically use sensors and software to measure various parameters and generate reports. They can also be programmed to perform specific tests and troubleshoot common problems.

Summary Table

| Test | Purpose | Steps ||—|—|—|| Temperature Test | Verify temperature distribution | Measure temperatures at various points in the space || Airflow Test | Ensure adequate airflow | Measure airflow velocity using an anemometer || Electrical Test | Check electrical safety | Measure voltage, amperage, and continuity || Refrigerant Charge Test | Verify correct refrigerant charge | Use a refrigerant gauge to measure pressure || Safety Test | Ensure proper safety features | Check smoke detectors, carbon monoxide detectors, etc.

|

Troubleshooting Flowchart

[Flowchart illustrating the troubleshooting process]

Not Getting a Permit

Obtaining a permit before installing an HVAC system is crucial for ensuring safety, compliance with building codes, and avoiding potential legal consequences. Installing an HVAC system without a permit can lead to various issues, including:

Safety hazards

Improper installation can result in gas leaks, electrical fires, or other safety risks.

Code violations

Installing an HVAC system without a permit violates building codes and can result in fines or even the removal of the system.

Insurance issues

Homeowners insurance may not cover damages caused by an unpermitted HVAC system.

Types of Permits Required

[detailed content here]The type of permit required for an HVAC installation varies depending on the location and scope of the project. Common types of permits include:

Building permit

Required for any structural changes to the building, such as adding or modifying ductwork.

Electrical permit

Required for any electrical work associated with the HVAC system.

Mechanical permit

Required for the installation of the HVAC equipment itself.

Obtaining Permits

[detailed content here]To obtain a permit, homeowners should contact their local building department. The application process typically involves submitting plans for the HVAC installation, paying a fee, and passing an inspection.

Tips for Avoiding Consequences of Not Getting a Permit

[detailed content here]

- Check with the local building department to determine if a permit is required.

- If a permit is required, obtain it before starting the installation.

- Hire a licensed and insured HVAC contractor to ensure proper installation.

- Keep a copy of the permit on file for future reference.

Popular Questions: What Are The Common Mistakes To Avoid When Installing An HVAC System?

What are the consequences of improper HVAC sizing?

Improper sizing can lead to inefficient operation, premature system failure, and discomfort due to inadequate heating or cooling.

Why is ductwork design crucial in HVAC systems?

Ductwork design affects airflow distribution, energy efficiency, and indoor air quality. Improper design can result in poor airflow, noise, and reduced system performance.

How does insulation impact HVAC system efficiency?

Proper insulation minimizes heat loss or gain, reducing energy consumption and improving system efficiency. Neglecting insulation can lead to higher utility bills and reduced comfort levels.